ELECTRIC SUCTION BLOW MOULDING MACHINES

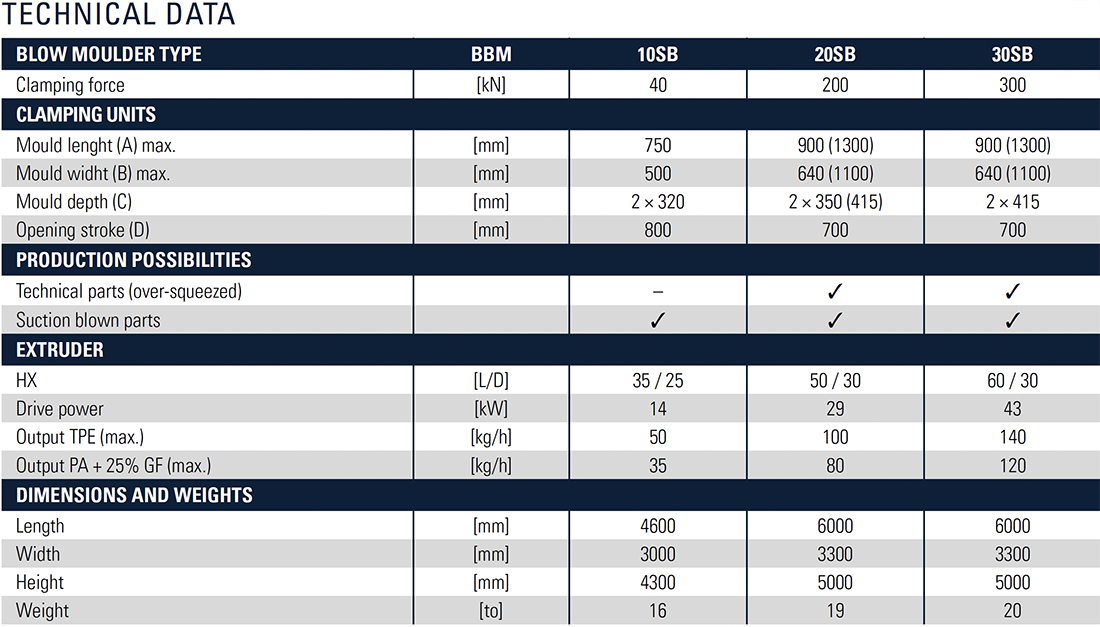

BBM 10SB

BBM 20SB

BBM 30SB

• Technical suction blown parts up to 1500 mm stretched lenght

• Stationary easy accessible clamping unit with proportionally controlled suction blow equipment

• Rigid clamping unit with solid tiebars and electric drive system

• Mould thickness and clamping force adjustment, directly at the operator panel

• More than 50 % energy saving, compared to hydraulic machines

• Electrically controlled movements for mould and die slider system

• Hybrid servo pump system for material pushout and wall thickness control

• Space saving due to unique design

• Easy access to the production and maintenance area with wide opening safety gates

• BBM ‚BlowControl 2‘ with Multi-Touch Screen and Remote Control

• High output extruders for technical materials (e.g. PA, TPE, TPU, PPS)

• Extruders allow screw removal to the back

• BBM high-performance accumulator heads

• Optional: die slider system, double accumulator head, robot take-out, post-processing, sequential co-extrusion